@tibberz , Hi Tobias! Getting ready to start shipping this batch of z-stabilizer and nozzle stabilizer mods to you guys! It’s been a struggle to do anything in the shop of late due to the cold weather, soon I hope to be able to endure for longer periods when warmer temps arrive.

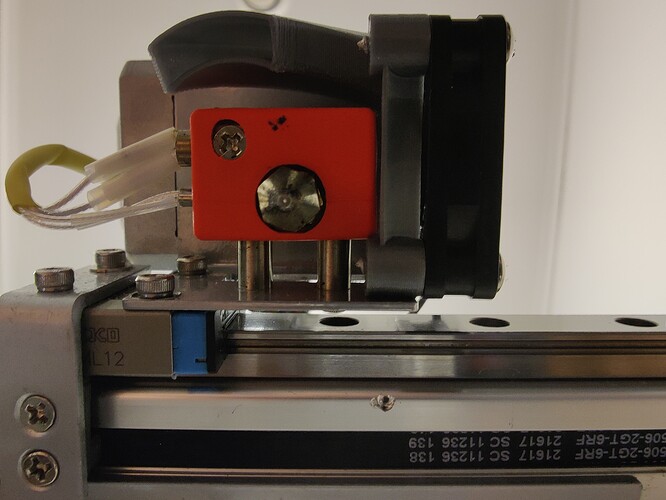

I would suggest a couple of spacers to the fan mounting but that would reduce the upper nozzle cooling. The upper nozzle cooling is extremely important to reduce nozzle clogs for this style of heatblock/nozzle assembly. The nozzle stabilizer mod you will be receiving moves the heat zone closer to the heatblock thereby reducing the need for cooling of the filament-entry-point of the nozzle, so you could then mount the fan with spacers to align the cooling duct.

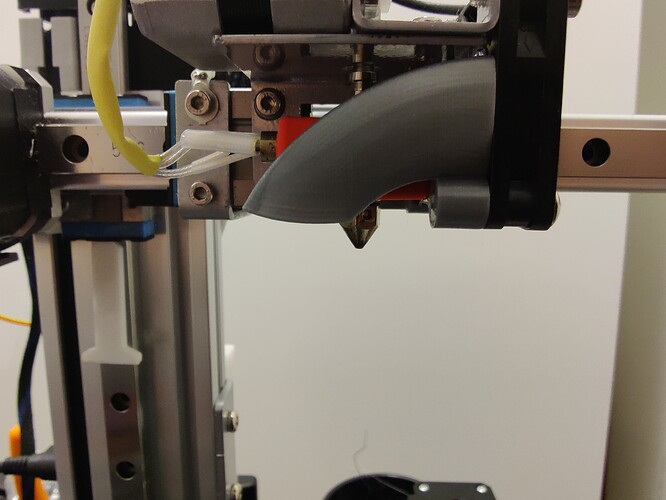

I prefer to see the nozzle tip while printing because I use a high-speed nozzle-cam to analyze and fine-tune the filament flow, especially when using exotic filaments. Until you receive your mod package you might try using the stock style of ducting.

When you install the nozzle mod you are going to be amazed with the boost in print quality… I was! That stupid-simple little mod completely changed my 3D printing experience. Waaay better-quality prints and combined with the z-stab mod… much faster printing! I just can’t wait to get the mods to you… I wanna see your jaw-drop and the perma-grin that follows.

I recently installed Slice Engineering’s Copperhead assembly and damn it’s awesome. I’m using their Vanadium nozzles… another game changer! I’m also using V6 E3D brass nozzles allowing for temperature-stable high-speed printing… how fast? …models without sharp direction changes… 110+ mms/sec …on proof-of-concept models when I don’t care about perfect-quality … 130-150 mms/sec…even at 130+ speeds the prints are a decent quality.

With the Copperhead upgrade I’m printing eSun PLA+ with a 0.15mm brass nozzle, the level of detail achievable is amazing. I ordered a few E3D V6 brass nozzles “undrilled” …yup…I’m goin’ sub 0.10mm nozzles for super detailed models. I’ll probably drill a 0.10mm nozzle first and then drill a 0.08mm nozzle. I’m trying to convince Slice Eng to provide me with a 0.10mm Vanadium nozzle, I don’t have the tooling to drill Vanadium.

Oh, I’m using a Boron Nitride paste for the heatblock components…important that it’s “Boron”… huge difference in heat-transfer compared to regular pastes, I’ve done the research and testing for you. Aaaand “Plastic Repellent Paint”… huge reduction of blobs deposited on your prints!

The other news is I’ve designed a new cantilever style 3D printer(same style as Cetus). It will integrate all the mods I’ve designed, the physics I’ve learned about the cantilever-style and more. The print-platform size will be around 200x 200mm, maybe a touch bigger. A completely new y-axis assembly that does not use aluminum extrusion and only the heatblock/nozzle assembly will ride on the linear rail… I know… you’re likely thinking Bowden …and you’d be partly correct… I’m calling it a “Bowden Hybrid”. The benefits of a Bowden system without the drawbacks/cons. I’m thinking open-source and completely modular, meaning, mix and match components. I wanted to keep the Bill-of-Materials list low and the cost low as well. There’s no way I can do this solo, I’m hoping to gather a team together and get things rolling.

If you purchase from Slice Engineering mention Brent from Technology Salad, who knows, you might get a discount or a lollipop.

Happy Printing guys!

Brent