I’m not saying you have modified anything, I’m just offering you some possible solutions to what I see.

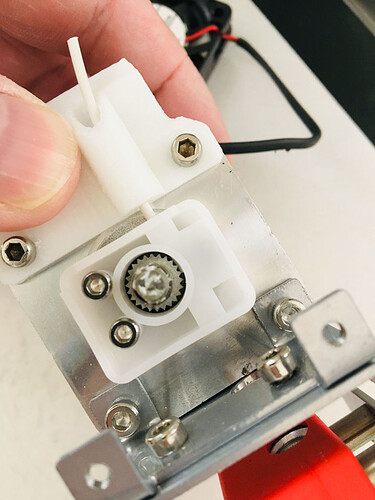

After some needed sleep, in the last video you posted, it looks like there’s too much tension on the filament feed. The extruder motor is struggling to feed the filament. I can see a build-up of filament shavings on the extruder gear.

Here’s what I would do to solve the problem:

-

Remove the extruder gear cover and clean-up the extruder-gear and surrounding area of filament shavings.

-

Shorten the filament guide-tube to about 50-75mm and insert it into the guide at the top of the extruder-motor, make sure the filament line from the spool to the extruder is not attached to anything and peels off the spool freely.

Hope this helps you get back to printing!

cheers!

Your view is certainly better than mine @rogermc , I can only go by what I see in the video  . If there’s no shavings great!

. If there’s no shavings great!

Was there too much tension in the filament path?

I noticed in this last pic there is some wear on the motor face where the upper-nozzle sits when installed. And on the other pic where I see the underside of the heat-block has some ridges where the lower-nozzle mates with the heater-block. It looks like the nozzle might not be vertical when installed. The filament might be catching on the sidewall in the nozzle where the stainless-steel attaches to the brass in the nozzle. You might try to make the nozzle more vertical when you re-assemble everything. The other thing that may be happening that contributes to the nozzle not being aligned vertically are the two tubes that attach the heater-block to the frame…before re-assembling the fan and ducting you might check that those two tubes and the fasteners inside are aligned to help with the nozzle being vertical.

I think the nozzle is too close to the bed. Try to add some nozzle offset in software.

Since my printer has been working flawlessly for several years, I see no reason to make changes to the hardware, feed tube length, routing etc. I also see no reason to deviate from the written documentation for calibration.

There is no excessive resistance or tension in the filament feed path. The extruder unit is as received from TierTime with the exception of attempting and canceling 2 or 3 print jobs which resulted in poor print quality. I can’t imagine that small amount of use could result in actual wear on the motor face.

In no way do I mean to disparage the efforts of those who have been working to help me resolve my problems.

I hope that TierTime support will respond to this thread and provide guidance please.

@rogermc , The only course of action left for you now is to direct your support request to the email address found in the written documentation you have used for your printer. If you’re not able to find the address, and would rather use only Tiertime supplied information/directions, then try clicking on the “Support” link found on the Tiertime Homepage. This course you have chosen is the “Community” link, which if used, is to mostly connect with the community of printer users …not necessarily like minded …but others that enjoy helping others using their wealth-of-experience and technical skills. If you don’t mind, I hope you will edit the title of this post to include “Official”.

Best of Luck to you

Thanks for your help!

@rogermc, your issue is a simple case of nozzle block.

To eliminate the possibility of it too close to the bed, do an extrude. If the filament doesn’t flow freely and that sound manifests, then the nozzle is blocked.

I’d belying if I don’t say I experience clogs too, but I have practiced an easy way of dealing with it.

- clog happens in the throat, where in my case a filament piece gets trapped for some reason.

- clog happens in the nozzle, which is more common.

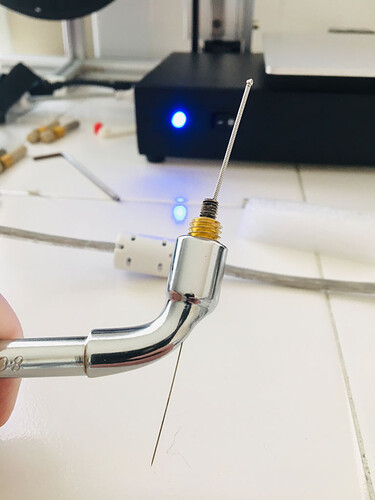

Fix I do is to disconnect the throat from the nozzle, as shown in the photo (photo not mine).

Next, check to see if the throat is clear of filament debris. If not, remove debris inside the throat. Check the nozzle for blockage, here’s my 0.4 nozzle blocked by hardened filament.

I clean the nozzle by installing the nozzle only (no throat) into the heater block and heat it to the temperature of the filament the caused the blockage. Insert the thin wire (included in the kit) and push it through (won’t go thru on a 0.2 nozzle). Turn off extrude (or withdraw) for the temp to go down and I start to pull away the debris. Repeat.

Here’s a photo of the debris I was able to pull out recently.

If I may chime-in here… to answer your question @rogermc , yes …your last video shows how well the filament flows under great pressure, not-the-same pressure as when printing beyond the raft procedure. Your last picture shows it’s possible there are small fragments of hardened filament(or combinations of debris and filament), as @Arnold shows in his picture. There may not be as many fragments as @Arnold 's last pic. I suspect @Arnold is showing the amount of hardened filament that eventually completely blocked his nozzle …your nozzle may be experiencing a few or one unwanted objects that intermittently disrupt the filament-flow under the less-pressure-printing beyond the raft layers.

I regularly clean my nozzles to ensure error-free printing and zero nozzle clogs, yup…I said it…zero clogs. But zero nozzle clogs require frequent preventative maintenance.

edit: when you follow @Arnold 's recommended procedure, you may notice, as I have, that sometimes debris gets lodged in-between the slippery white-tube and the interior wall of the upper stainless-steel nozzle. This will pinch the tube, further restricting the free-flow of filament. You’ll never know for sure until you follow @Arnold’s excellent instructions.

cheers and happy printing for everyone!!

Unfortunately I am unable to perform the operations needed in the excellent instructions.

I have never had any nozzle blockage in years of usage.

The nozzle I am using was new, provided by TierTime and has had essentially no use.

I have no ability to separate the throat from the nozzle.

I will order replacements but am not optimistic they will resolve the quality problem. I will be waiting several weeks for them to arrive.

I’ve contacted TierTime several times, but so far they haven’t provided any help of value.

Thanks!

Do you have a friend or someone near you that has a pair of pliers, even easier with a small vise. Once the nozzle is disassembled you could use a sewing pin to work-out whatever is lodged. The other thing that can happen, and has happened to me with a brand new nozzle, is when the nozzle is assembled at the factory, the short slippery white-tube in the upper nozzle is too-long. What happens is, when the upper-nozzle is tightened onto the brass part, the white-tube buckles and makes the white-tube oval or even pinched enough that the extruder motor does not have enough torque to push the filament through the constricted opening. This can even happen mid-print because as the motor heats-up, the motor’s torque decreases slightly, and sometimes without sufficient cooling the ambient temperature within the motor heats-up over the operating temperature of the motor…effectively robbing the motor of available torque to get the filament through the constricted white-tube.

You’re welcome @rogermc , I’m rootin’ for ya …hope you get some decent nozzles, you shouldn’t always trust new stuff in this extremely competitive marketplace.

Thanks techsalad, after years of flawless performance I am completely baffled.

I ~was~ able to separate the throat from the nozzle using more force than I really wanted to apply. What I found was the remainder of the filament that I would expect to see after doing a withdraw. It came out of the throat very easily. Throat is completely clean as a whistle.

I then installed the nozzle only and started an extrude step. Once up to temp, I removed the nozzle and fished around with the cleaning tool. With just a small amount of effort I was able to pass the tool completely through the nozzle. I suppose there could be some traces of plastic remaining, but since I cleaned the path I wouldn’t expect them to obstruct extrusion.

Here’s the photo

That’s great!

Now… can you check the upper nozzle where all the problems seem to arise.

This is what the mating end, upper nozzle…throat should look like:

This has been cleaned of debris.

Brent

---- excellent, and the white tube condition?

----I use a piece of filament and insert from top to make sure there is absolutely no friction, preferably the largest diameter…you may have to measure the filament to find the thickest area. I use a filament that is .178mm in diameter.

----the tube must be white as white can be

----oh, I did not see a bowden setup in the past vids?

----I mean the white tube inside the throat

----are you using a piece of filament that has the gear markings as when it passes through the extruder motor area?

---- what I mean is, as we are testing stuff, you need to use a piece of filament that has the bite marks to properly emulate the filament that normally passes through…and if there is no white tube, has this nozzle been re-engineered from the factory and the use of the white tube is no longer necessary?

----I’f there’s no PTFE white-tube in the upper nozzle throat this will over-heat the filament and will quickly disrupt the flow of filament. There’s a ridge the filament must get past if there’s no white-tube.

Sorry, don’t know what the upper nozzle would be. Isn’t the upper nozzle called the throat?

The throat is completely clean, not a trace of anything.

Bowden tube is clear, no friction. Same condition as when printer was new.

Sometimes when I re-insert the filament before an extrude, I forget to attach the tube. Has never seemed to cause any issues without it.

There is no white tube inside the silver upper nozzle - at least not that I can see.

In any case, my filament passes easily through the upper silver part of the nozzle.

I clip off any parts of filament which show “bite marks” before inserting the filament.

I think at this point, I will try to print with a different fresh filament.

Changed to a different filament. It will print about 3-4 lines and then just STOPs.

Bite marked filament passes easily.

I still think there is something more seriously wrong with the printer. But, TierTime is probably the only one who can answer that. Maybe my model has a known defect.

I’ve had enough for today. Maybe TierTime will respond tonight with something helpful.

Thanks for trying, Brent.

Hello,

To me, it looks like it is extruding too much.

Are you using the customized print profiles? Have changed line width setting?

What is material and print setting?

Hi Jason

Thank you for responding.

Software is Up Studio 2.6.2. (571) on macOS 10.14.5.

I am using PLA, including TT PLA. I have no way to customize so use TPU for 230C temp.

My temp is 230C with 0.4mm nozzle. If I use a lower temp then I get the clicking sounds.

Print settings include:

Layer Thickness: 0.2mm

Quality: Fine

I have made no changes to line width, and see no option to change it in my software.

Why would the printer just suddenly stop printing? This is the symptom several weeks

ago when all my trouble started. The printer has not worked properly since then.

There should be a 3mm OD/2mm ID PTFE tube inside the throat.

Do you want to try a gcode I can give you a link to?