Hi, I finally found out why parts sliced by Prusaslicer (friend of mine has it) are printed (on other printers) much more solid and strong when Fill is 100%: it’s because the Prusaslicer has a path mode called “Gap Fill” which will fill up even the most narrow gaps between walls!

Is there any chance we will ever have this in Up Studio 3? Or is there any way to get there in a different way? I desperately need true 100% fill rate for my parts, I can’t accept random gaps here and there and it’s not acceptable either to design parts differently just because the software won’t fill gaps.

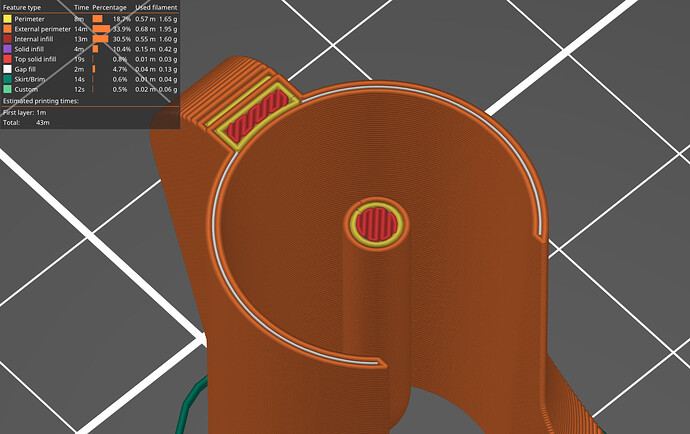

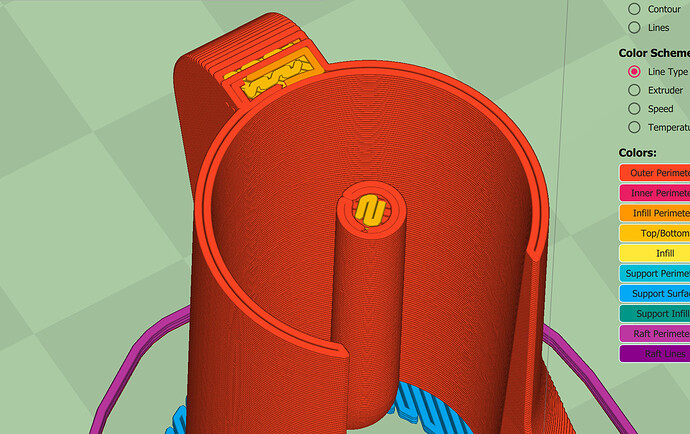

For comparison, see these images here, look at the top rim of this part (wall thickness at the top = 1.0mm), closed-off in Prusaslicer with the white colored “Gap Fill” path, but simply an open gap in Up Studio 3: