@Jason-TT, bring back the OFFSET!

@Arnold. You can manually adjust the height offset in Wand using the “Height detect” feature. You can use the +/- buttons to adjust then click ok. This is essentially the same as using the offset feature UpStudio 2 as it just added this value to the calibration offset.

I don’t know if anyone else has this problem but for me Wand crashes whenever I start a print. I manages to send the job to the printer but never thinks it’s finished.

I’ve just been shutting down Wand and restarting it and then it shows the print running.

Wand also says it can’t connect to the printer every time it starts even though it does connect and works fine otherwise.

I’m using UP300 via wifi.

I know that, but I prefer having a baseline and adjust the offset depending on the nozzle/layer height for my print.

@Jason-TT, after 100% successful prints, Wand doesn’t detect the temperature for both nozzle and bed. I first noticed this when Wand was stuck to “sending print” but my bed has reached 75 degrees already.

It was not a printer issue as I’m back to UP Studio 2.6.5 and everything is back to normal.

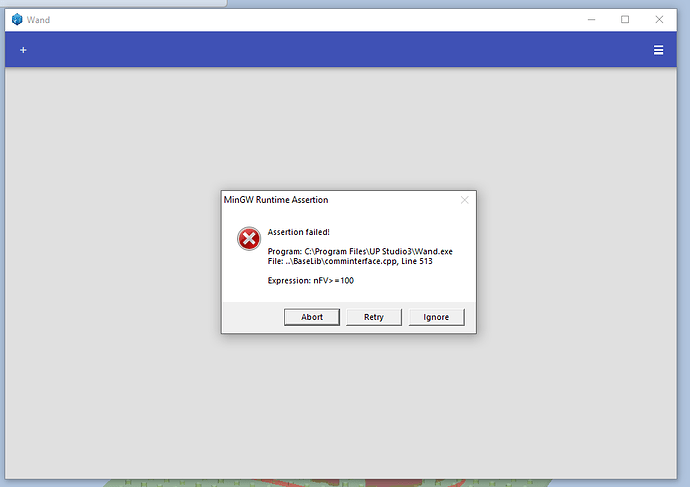

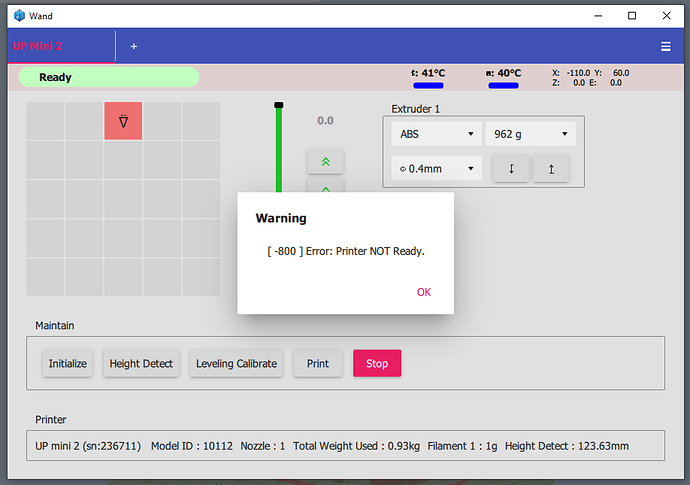

Windows 10. Every time I open wand to print I get the error message.

I can click retry and it just goes away. If I click ignore then wand will open. I have to click it a few times. I can’t send a print to the printer and if I try to choose the task file manually inside wand it tells me the printer is not ready. This is even after I click initialize.

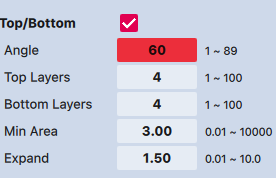

Increase the top bottom surface angle to trigger the top dense layer to cover the gap.

hi, I stil dont get it. i hae allways the meterial ID not match.

- start UpStudio3

-

- add stl file

- slice 3d models (on the top ABS is selected)

- print 3d models - wand is starting

- wand - connecting to up300 printer

- there is no tsk file so I dont unterstand which stk file should I choose ??

- now I am saving 3d model to sliced tsk file

- i go to wand and chose the tsk file.

- wand - material- edit - material in use: abs, Available Material: none

- import from tsk: no additional materials are shown

can you please explain how to solve this problem ?

thanks!!

the material in machine has the name ABS but may be it is a custom profile has the name ABS but actually different material ID?

I have up plus 2 and I have same issue with 2.6.5 version it is stopping mid print in specific point for same print, also earlier versions are not working appropriately (only 2.4.0 works but infill options are not working in that version. Forcing %99 infill)

that is a known issue for older machines, please use v2.5 UP Stuido. We will try fix this problem in UP Studio 3 but still not solved yet. You can also get the wifi CPU kit to solve this problem.

I tried to download v2.5 to my mac but when I try to install(2 times) nothing happens(it says successfully installed but I can’t find app and I checked from everywhere) also something wrong with that file because I can download other versions on high speed but v2.5 downloads with kb’s which makes the situation a lot worse. Also I wrote support for cura settings, as you know I can’t get prints like that and they choose not to respond (g-code which is given in g-code tutorial is not working.)

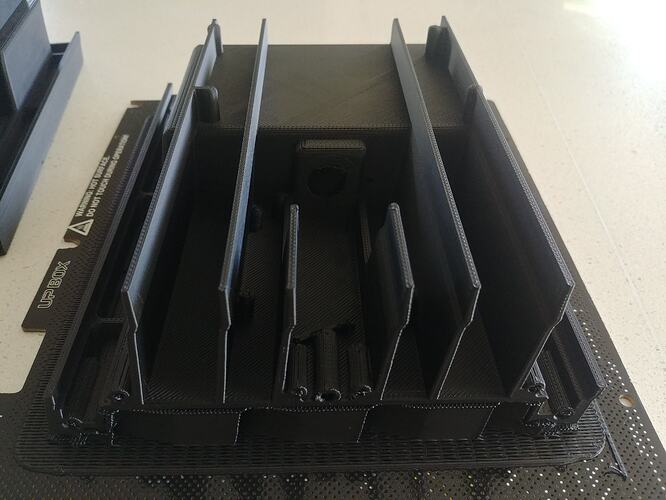

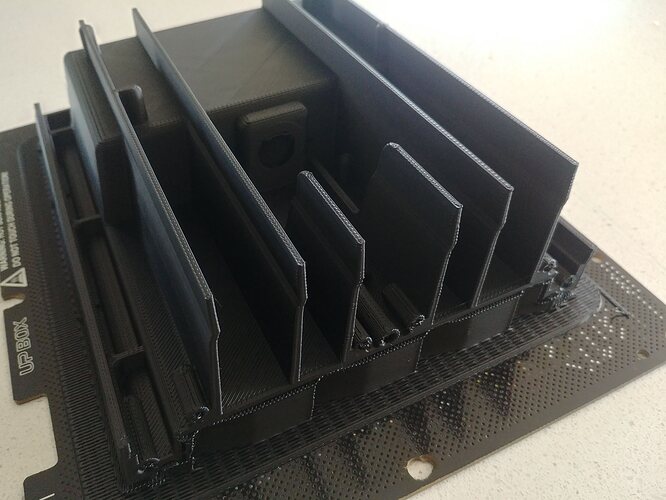

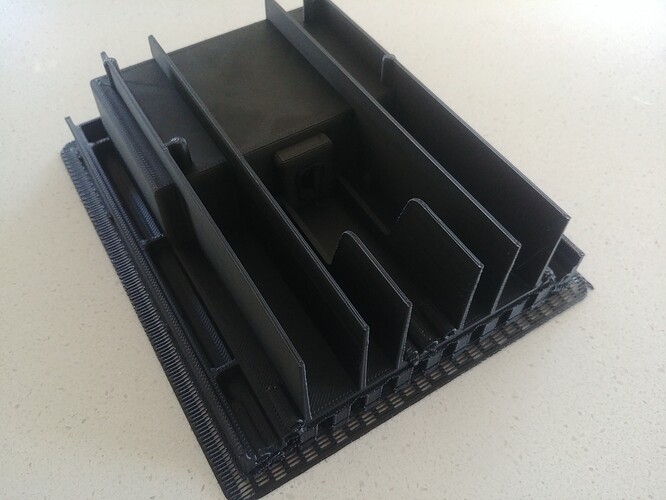

I’ve got a problem printing a large ABS part. It slices and prints fine when using a chamber heater to stop the layers from cracking.

The problem I’m getting is the print starts to ‘lean’ across to one side, and then fixes it self. I think what’s happening is the stepper motor for one axis is stalling causing some deregistration as noted by strange layer shifting-like results.

I’m printing this now in UP Studio v2.6 to see if there’s any difference.

Following on from my post above, this part printed in UP Studio 2.6 with the same equivalent print settings came out fine…

Has anyone noticed any strange printing effects with UP Studio 3?

Can you also see the strange effect in the preview in UP Studio 3 ?

Hello @Jason-TT, I did check the TSK file preview in UP Studio 3 (v3.0.17) and it does render the job correctly without the leaning.

What I think is happening is a stepper motor is stalling on one particular axis causing the lean to carry on during the print, and then cease as it gets to the top of the lid because perhaps the layer seam is shifting to a different location such that the stepper motor(s) aren’t stalling.

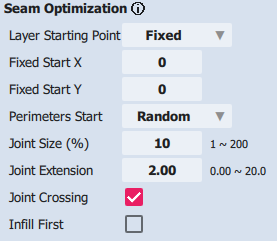

I have my seam option setup to start perimeters at random locations to avoid a big long seam running through my prints:

Using USB with my Up Mini 2, I often get the error [-1600] Error: Transfer Failure (BLOCK SIZE).

Would updating the touchscreen version fix this? Am I able to update the touchscreen with the version made for the Up Mini 2 ES?

Anyone know the answer to my previous post?

UP mini2 cannot update firmware using the ES firmware.

UP mini 2 does not have firmware update available.

The error could due the software issue, you may try update to latest version. (eg UP studio 3.1.1)