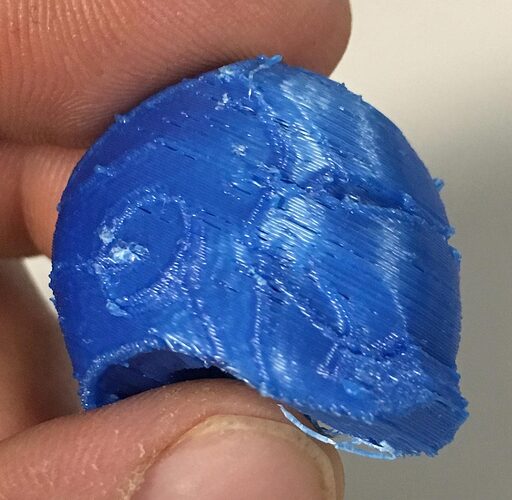

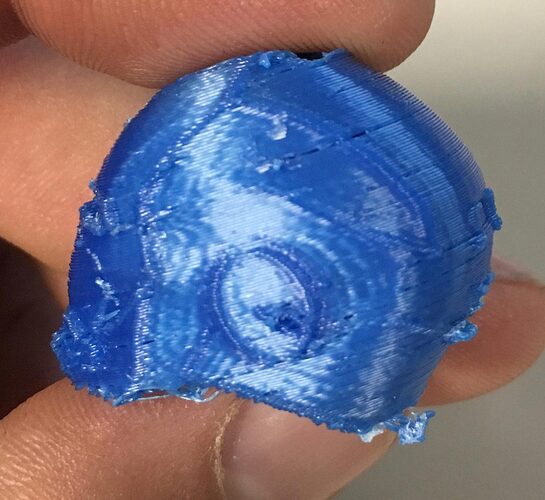

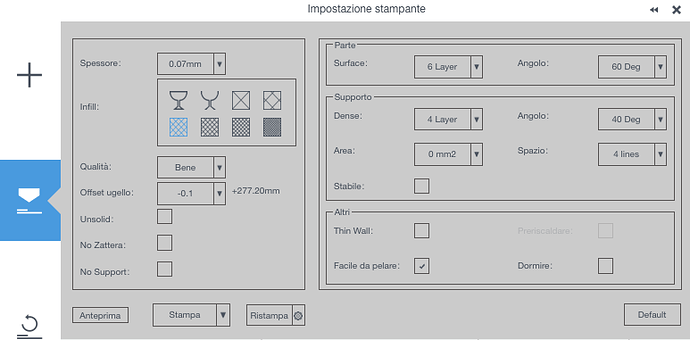

Hi everyone, I just upgraded the nozzle by putting the new group with the steel terminals … unfortunately the print quality has deteriorated drastically … I’m trying different combinations of temperature and quality but the result is always bad. Where do you think I’m wrong?

Can you provide some more details…material, temp setting, nozzle size, layer height, line-width. Looks like a temp problem at first glance. Did you re-calibrate your nozzle height? Also check the two screws that fasten the hotend/nozzle assembly.

Pla at 215°c

I noticed that the tip of the extruder is now a few millimeters lower, could it be the refill of the fan that is no longer aligned well? (instead of cooling the material hits the nozzle)

Steel nozzle? You need to increase the nozzle temperature. Try 10 deg higher.

Printing at .07mm requires the calibration(nozzle to print-bed) to be perfect and the temperature must also be tuned for the steel-nozzle as @Arnold has commented. When using steel nozzles, heat does not transfer like a brass nozzle. And if you are trying to print at .07mm with a nozzle larger than .02mm the settings must be tuned. Those extra deposits of plastic, blobs etc are from too much plastic being extruded from a larger nozzle and the very thin layer-height, the extra plastic gets pushed on the surface, and also will stick to the nozzle-tip and then randomly transfers to the model surface. Also a print-speed not tuned to the nozzle temperature when printing at .07mm will stretch the filament too-much and look like long holes on the surface.