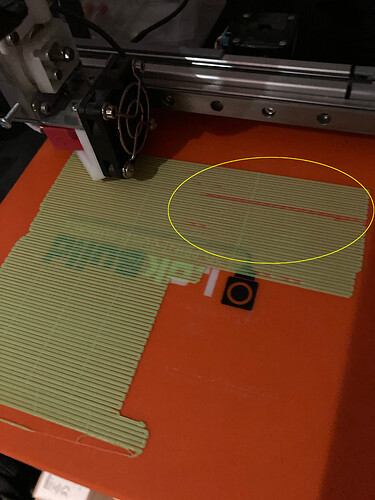

Sometimes the printer makes a thumping sound when it’s on the first layer of the raft. If the calibration is wrong and the print head is too close to the bed then it happens a lot, I assume it’s the filament crank jumping because it can’t force it through. But, even if the print head is not too close to the bed it still happens sometimes, and where it happens seems not to have any relation to the area of the bed that it’s on. See picture, the circled bit is where the thumping happened this time. Might this be something to do with the filament? It’s generic from Amazon, not the cheapest but not premium either.

I’m watching this topic as well. I’m having this issue on my MK2. I’m also getting some weird tearing on the first model layer followed by a layer shift.

cloaked nozzle or temperature issue. If this printer is used for years it may be something with the ribbon calbe on top of the extruder but first check the first options I mentioned.

I have started having this same issue on my MK3. I’m getting thumping, big blobs of filament on my raft layer, and whole sections of the raft without anything getting printed.

I replaced my nozzle, leveled the bed, and still nothing.

I put in a support ticket tonight. If I hear back do you want info on what they say?

I have exactly the same issue since yesterday. Would you please let me know what the support told you about this? The weird thing is that it only happens when printing. When I click “Extrude” in the maintenance-window, the filament is pushed out correctly and smoothly.

So far I tried the following things:

- used a brand new 0.4 nozzle to make sure it isn’t clogged

- used a different brand of filament

- decreased the printing speed by setting the quality to “Fine”

- tried different “Layer Heights” in the print settings

- increased the heat of the nozzle to 220 C°

- made sure that there is enough space between nozzle and printbed. The clicking sound and underextrusion also happens when printing 1cm above the printbed.

- reset the printer to factory settings (via up-Studio Software)

- took off the extruder cap and checked the extruder gear - it is clean

The problem still persists, I can’t print anything.

Edit: Tried to print with a 0.6 nozzle today, and the extruder gear can’t turn at all. No filament comes out. I suppose it could be a problem with the heating element. But then, why can I extrude when I use the “Extrude” command?

I managed to fix it. My problem was a broken extruder cable. I carefully took off the ribbon connector on the extruder-end, shortened the cable by 2cm and cramped the connector back on - done.

If some pins on the connector-cable get loose (which happens over time), the extruder may not work correctly. If you don’t feel comfortable with fixing the cable yourself, you can get a new one for ~10$. Hope it helps…

Mine ended up being a scratched build plate (I just have a simple coated plate, not a heated one). Turns out it got damaged in a recent move, so the extruder was scraping against the grooves, blobbing the material, and pushing everything either too close or too far. Ended up getting a new plate and extruder, reset the distance settings, and re-leveled the bed, and it finally fixed the issue.

I’ve also suffered from this issue. The solution is actually very simple.

When the first layers of the raft are deposited onto the build plate, they are over extruded by such great amounts it causes the extruder to slip. It simply cannot push enough material through the nozzle fast enough.

To prevent this from happening you can do one of these things:

-

Don’t use a raft. Take the time and level your bed correctly by shimming it around the mounting holes. As close to perfect as possible. This also requires you to square up the z axis to the build plate, as precisely as possible. The whole purpose of the raft is added support for the initial part layers but more importantly it creates a level surface your part is printed on. The 9 point matrix leveling really doesn’t do you any good unless you use a raft.

-

Verify that you’re setting the nozzle height correctly. I had success with the paper method. Use a piece of paper under the nozzle when calibrating the bed leveling you will feel a slight drag on the paper. However, I always bump it up one more click so there is no drag… this process is extremely critical and by adding that extra .1mm up from the point you feel that slight drag - caused me great success! You will have to use a raft for this method.

-

If you are confident you’re using the manual bed leveling correct and your nozzle isn’t too close to the bed then go into the material settings editor. You will find the ability to change the settings of the nozzle temperature, amount of layers and most importantly - THE SPEED - of the raft. I spent nearly 2 hours just making rafts and this really proved to be the solution to the popping sound you hear during extrusion of the first layers of the raft. Increase the nozzle temp, and slow that raft speed down. I took the time to optimize the speed setting so that the extruder didn’t slip but also didn’t take forever to print. HOWEVER! I learned that not all rafts are equal. You might set this for a raft and it works perfect but on a different part have the same popping issue as before. So. Just slow it down and suffer through the longer print times.

I hope this helps you guys.