Disclaimer: Don’t do this…

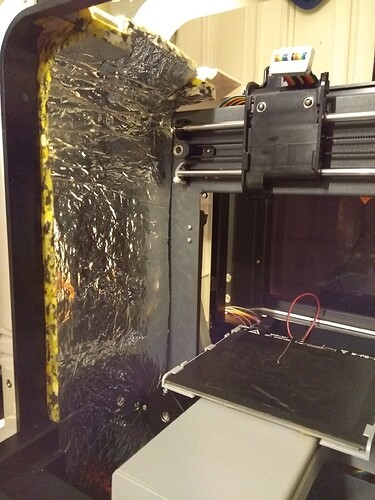

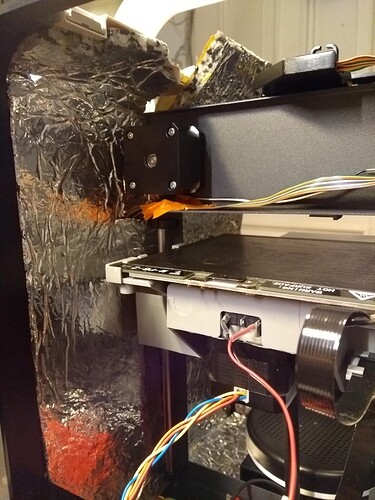

Background: This is a decommissioned Up Mini 2 that will undergo changes to mitigate the problems this modification will create due to increased chamber temperature that will cause the plastic parts to fail (namely bed assembly, linear guide holders and belt idlers).

To help with the warping when trying to print larger ABS parts I’m trying to decrease the heat loss to help keep the build chamber hot.

While sold as sound dampening, the self adhesive 10mm sheet of aluminium clad foam will also withstand temperatures up to 120C and help keep the heat in. And a thinner 2mm sheet for parts that need clearance, over the extruder and where the filament path is.

D’oh, forum is saying max file size is 30Mb, but rejects 2MB pictures… Will add when fixed…

Seems to reach 78% of the target temp for Tiertime ABS+ now, and room temp is around 18C. So it helps a little. Notably cooler sides, but front and back windows will be getting some window film to reflect heat back into the chamber, rear window is useless anyway so it may get a sheet of foam… But the metal frame inside does conduct heat out in a small area of the middle of the printer, where the handle is. May end up dissembling everything and adding some thin isulation between the outer plastic and the metal if there is room.

Update: 82% at the end of a 1hr print. Now to fix the bed…