cmeyer 2017-4-5 02:41 edit

!!CAUTION!! Your chances of damaging something are greater when you run gcode. Don't run somebody else's gcode w/o knowing what you're doing, because the nozzle offset is part of the gcode, so you can scratch up your plate. For the same reason, you should always re-generate your gcode files when your offset changes.

Some of the settings I'm using (start/end g-code, extrusion multiplier) are based on S3D settings from here:

- https://www.cetus3d.com/community/forum.php?mod=viewthread&tid=210

Note: I haven't tried this, yet, but I suspect the Y axis will be mirrored because of the unusual coordinate system and at least in slic3r I didn't find a way to mirror the Y axis

slic3r setup:

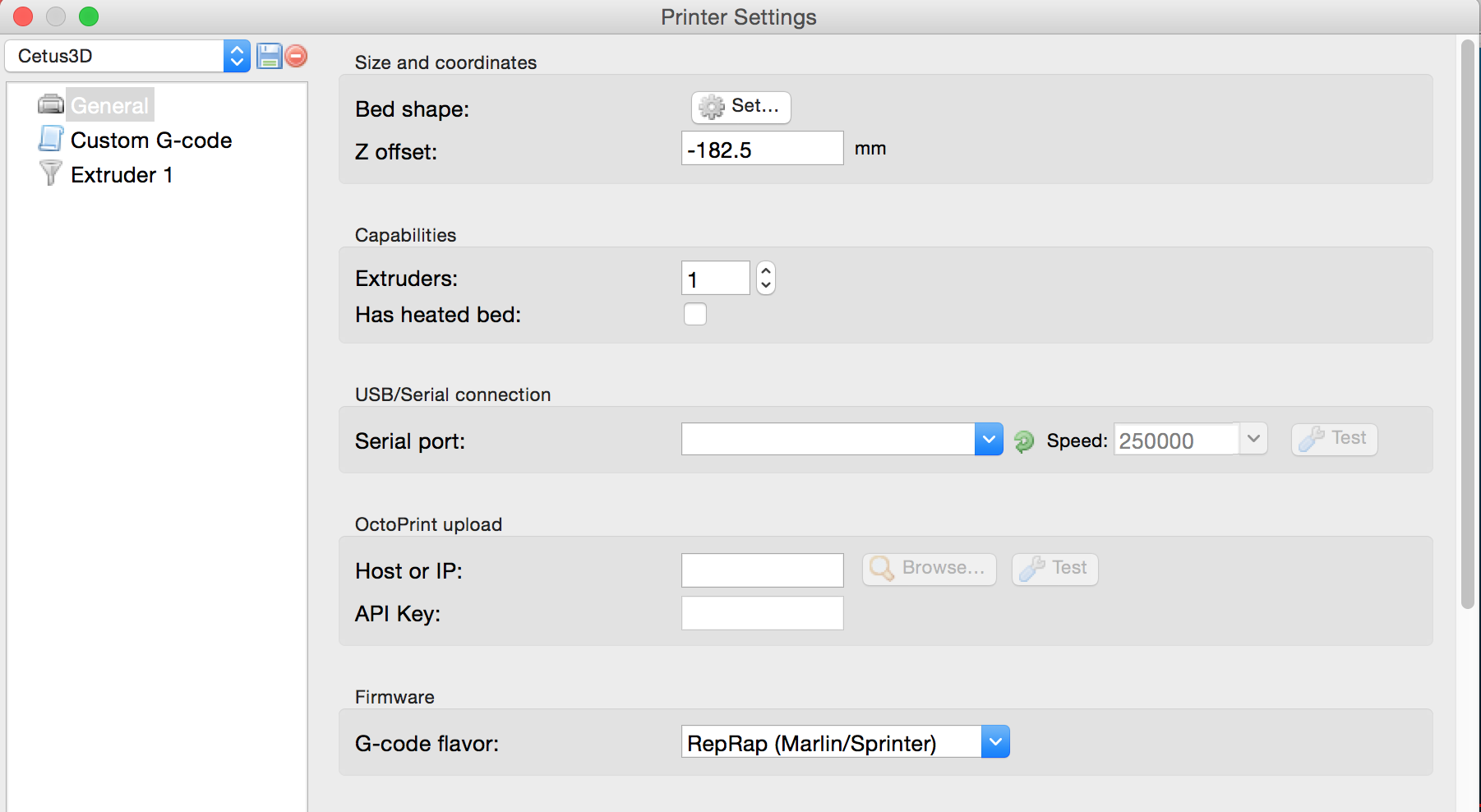

- general printer settings Z offset: -180 (change this to 0 - (your nozzle offset), so in my case -182.5)

- general printer settings g-code flavor: RepRap (marlin/sprinter)

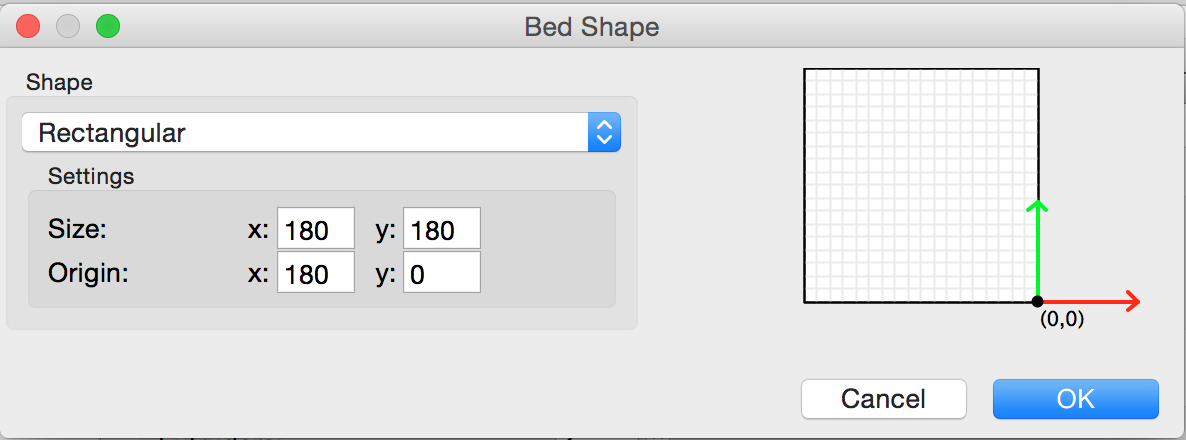

- general printer settings bed shape: size 180x180, X origin 180, Y origin 0

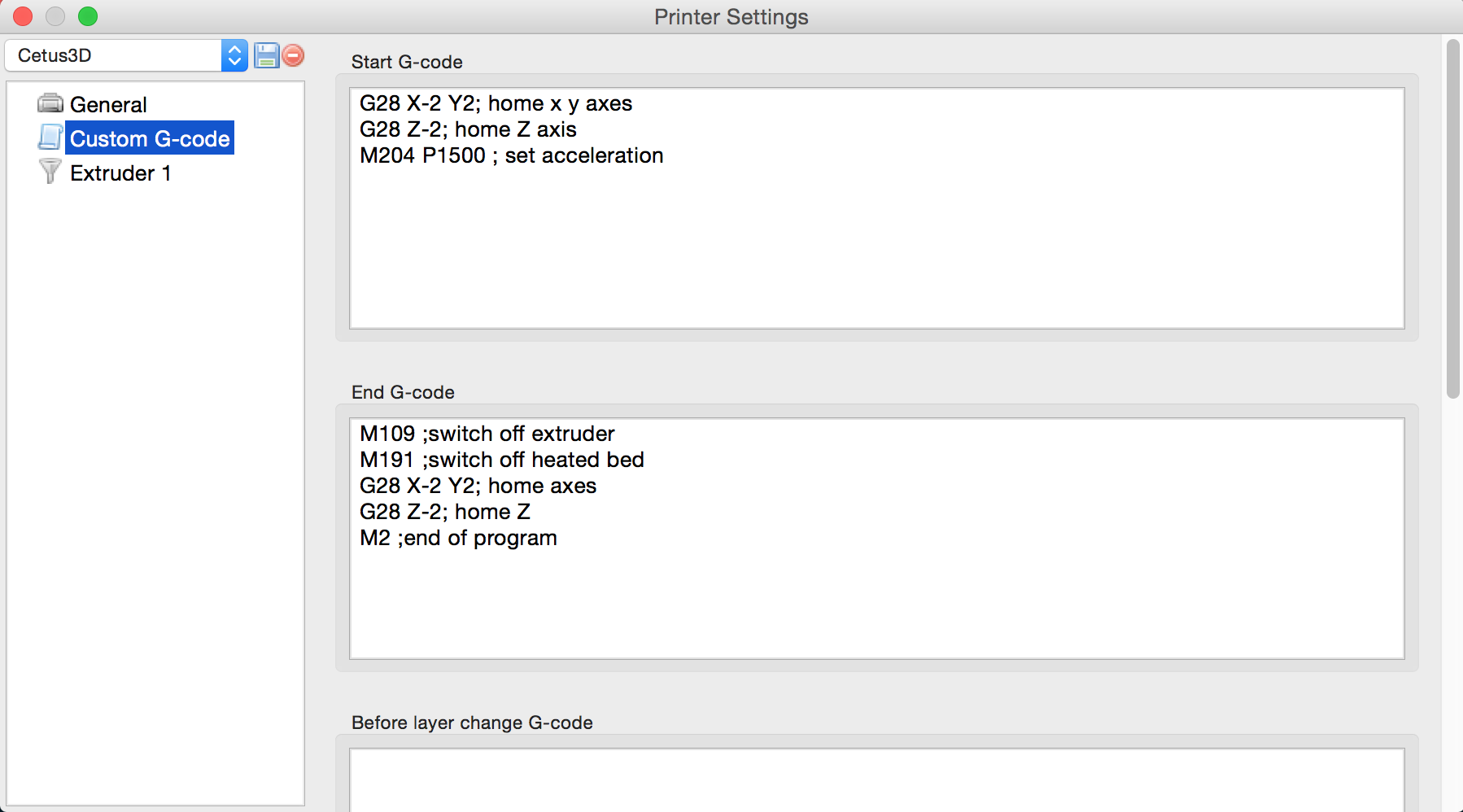

- custom g-code printer settings start g-code:

G28 X-2 Y2; home x y axes

G28 Z-2; home Z axis

M204 P1500 ; set acceleration

- custom g-code printer settings end g-code:

M109 ;switch off extruder

M191 ;switch off heated bed

G28 X-2 Y2; home axes

G28 Z-2; home Z

M2 ;end of program

- extruder printer settings nozzle diameter: set to whatever you're using

- filament: set diameter to 1.75

- filament: set extrusion multiplier to 20 (this needs more tweaking)

- filament: set temperatures

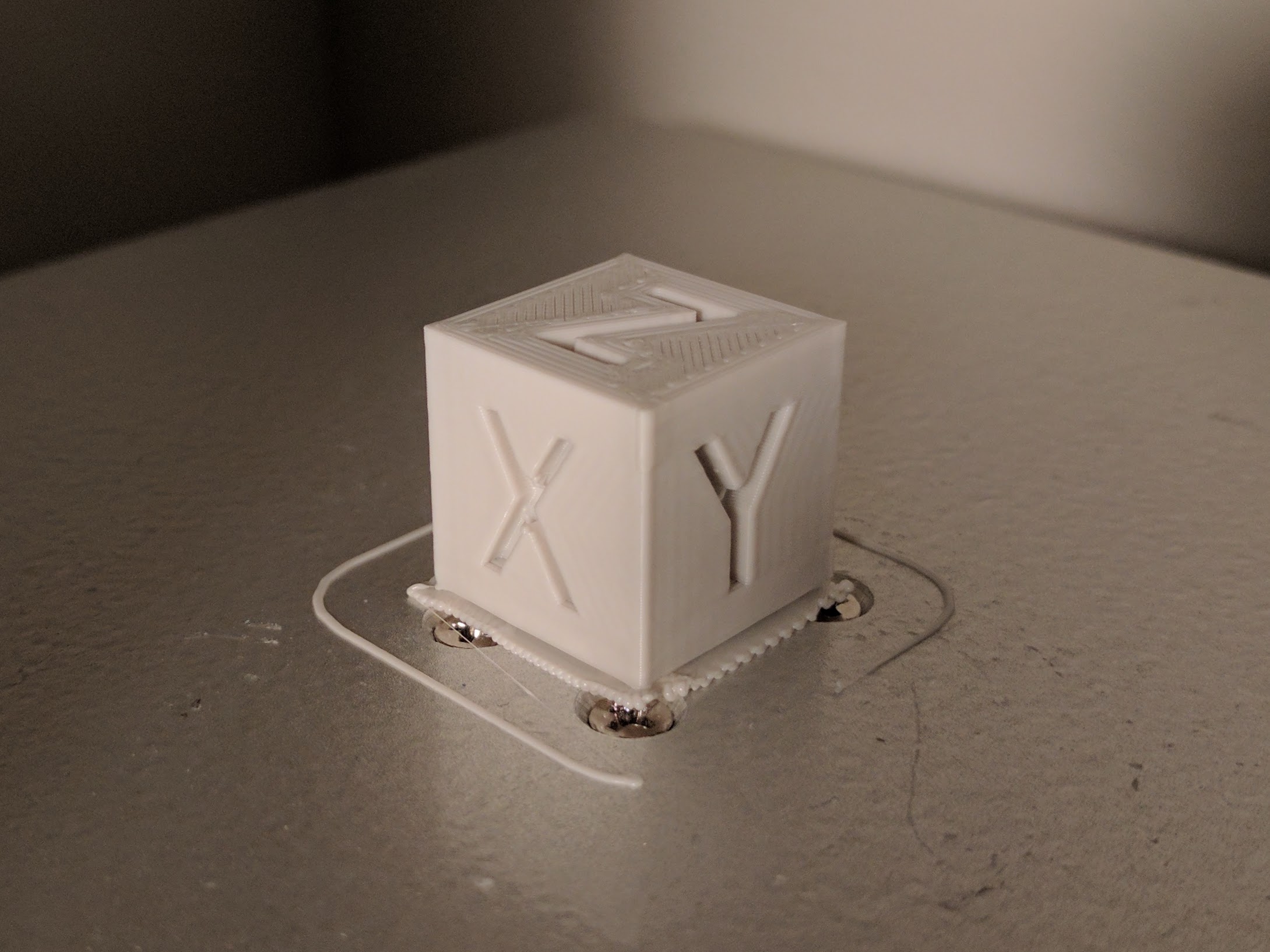

I tried a calibration cube with these settings and it obviously needs more tuning, but looks like the basics are working.