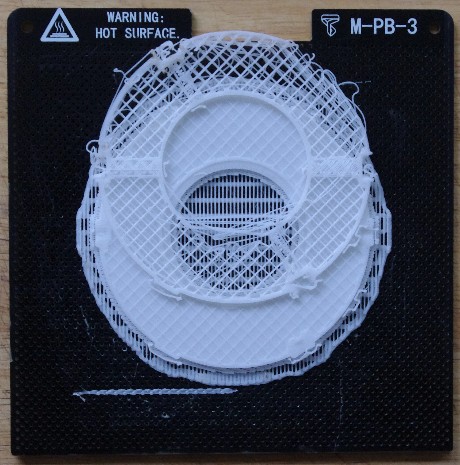

My 3-year-old UP Mini has suddenly started printing off-center (about 1cm too far back) and also shifting part-way up the print.

A few mm/layers up there is a nasty grinding noise and the print ‘footprint’ shifts backwards, then continues in this new position.

I’m guessing the drive belt is slipping on it’s gear?

Is this something I can fix myself by adjusting something?

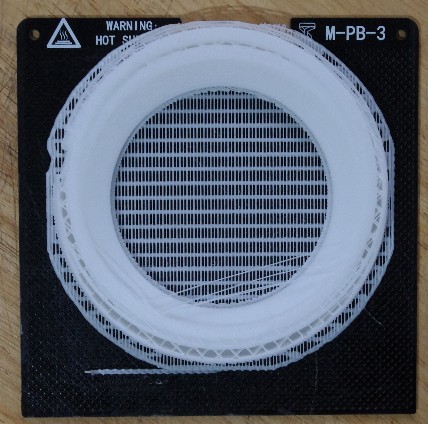

Here’s another example. UP Studio sowed the circle fitting perfectly centered on the bed, but you can see it’s hanging over the back. And then it shifts.

For my Up Box that is the X axis but anyway, check that front/back axis for a loose connection. The Up Mini moves the platform in those directions so that is probably not attached well enough anymore.

For the Up Plus (2) I used to glue the 3D printed part attaching the platform to the belt with a little superglue for less movement,

The horizontal drive train for the platform is completely enclosed in a plastic box with no visible screws. Does anyone know how I get into it to see if anything’s loose or broken? I can’t find anything similar about maintenance on the net, eg youtube.

there are screws under the whole x axis assembly (and yes, tiertime have swapped x and y - it would be y in a normal cartesian system, but its x in a tiertime printer…)

Thanks for that, Bjorn - I would never have found them buried in there if I hadn’t known they were there to find. Sadly now that I’ve opened it up, I can find nothing broken or sticking. Clearly the belt has been slipping as I suspected, because there’s black dust deposited around the return roller gear. On dismantling further, I see the four bearing rings under the bed are lined inside with pink stuff that is heavily abraded on two. I’m guessing this is some sort of lubricating material and the rails are now binding sporadically (though everything moves smoothly by hand). I’ve oiled these bearings and just done a test print, which worked fine. Will see how long it lasts. Maybe I’ll try some grease when I can get some.

I’d add some pictures of that and see what Tiertime (or your vendor) says about it; that does not sound like normal wear and tear.

My up mini 2 (not ES) have dry self lubricating bushings, if ES is the same adding oil is likely to be a stop gap solution.

For thin wall structures, please print slower on UP mini2 or Up mini2 es. The printer tend to shift layer on X direction if speed up too much as the thin wall infill cause rapid back and forth movement. You may try use “fine” mode or make a custom profile with reduced speed and acceleration.

My UP mini 2 ES is doing this too, several hours into the printing.

It’s happened before but now it is happening each time.

I did a smaller 1 hour print this morning, that worked okay.

I am sad

How old is your mini? As you can see from my earlier post, I opened my mini 2 and found the four bearings on the two rails underneath the print board are worn. I oiled them and it’s been running OK since. I’ve left the top cover off over the rails and replaced the print board, so the bearings are easy to oil again should it be necessary.

Still don’t know why it’s printing off-center to the rear.

I am also sad (and sorry I didn’t buy an Ultimaker…)

UP mini 2 ES - One and a half years old, but low usage.

I am having the same problem.

I believe that it is the stepper motor being instructed to move too quickly, which gives the tell-tail buzz noise, rather than the belt slipping.

So this is a slicer/hardware interaction issue.

I have better results running on FINE mode, but it is still happening…

I had that after upgrading UpStudio, older version was fine. I’ve not use the very latest much but it seems ok in limited testing. Jason claimed the new version should be compatible with all older models which I take to mean Up Mini 2’s can use without loosing steps

I’ve also had the idle pulleys fail so you might want to initialize the printer and try to move the axis by hand, it shouldn’t move. Use light force as you don’t want to overpower the motor, just see if the pulley will slip. Or you could try to check the belt tension but unless you know what the normal is its hard to describe.

Looks like a sticky bearing to me. Happened to my UP Mini (original ) around 20 Kg… I just regreased the shafts the bearings move on with some high temp silicon grease, all good again  Might not be the same problem, but it looks like it.

Might not be the same problem, but it looks like it.

Hello,

We have four UpMini Printers and all of them have the same problem. They shift, and we have already tried printing in Fine mode.

I would appreciate if someone could share the way to fix this problem as it seems is common.