Has anyone figured out a quick way to swap nozzles without the laborious task of bed leveling!?

The thought of changing out nozzles is putting me off prints as I just can’t be bothered…

Has anyone figured out a quick way to swap nozzles without the laborious task of bed leveling!?

The thought of changing out nozzles is putting me off prints as I just can’t be bothered…

For which printer is your question?

I’ve got a Cetus mk3

@onis_uk , yes …I have three designs that tackle the common laborious tasks connected to nozzle swapping.

One is a nozzle-mount that encapsulates a nozzle which then slides into a custom heat-block. Another is the same nozzle-mount used with a detachable heat-block, so the heat-block assembly becomes a plugin device. The last design is the heat-block assembly with a filament type already loaded into the nozzle as a plugin device. So each plugin device would have an identifier with a z-axis offset to use when slicing… you could further customize the z-offset taking into account for the filament type if needed.

I have no-idea when I will be able to publish tho, heck I haven’t even introduced my z-axis mod yet, which is only days away now btw

cheers!

Ok, I have the same and I wonder where your challenges lies as I don’t have issues with nozzle change with “laborious” leveling.

So you don’t do the full 9 point level when you change a nozzel?

No, I did that once when the printer was new. I didn’t see the reason why I have to do that again.

Well because when change the nozzel and mess about with the hight etc is it not worth doing?

I think the entire process from Tiertime isn’t clear in the instructions what should be done with regards the bed leveling etc @Jason-TTwhat is your recommendation on the matter?

I don’t understand your challenges when changing the nozzle. I have 0.2, 0.4, and 0.6 nozzles. They all have the same height, only the opening is different.

This is how I do it - roadtonirvana.net/diy/Cetus3D-leveling.htm

Shouldn’t have to level the bed even if the nozzle height changes, just adapt the overall z-height if for some reason the new nozzle installs with slightly different height.

The 9 point bed leveling should only be needed if you replace the bed or make changes that affect the alignment of the x/y plane with respect to the bed.

Am I right in thinking if I want to start printing raftless, I need my Z height to be equal to the layer height I intend to print in? ie 0.2mm layer height, my nozzle height needs to be set at 0.2mm from the bed…?

You can print without raft like I do if you have a glass on top of the stock (or heated) bed.

Set the nozzle height (Calibration/Level Calibration) to as close to the glass without scratching it. I use a 0.05mm gauge to make my life easier or I just do a visual check which is easy with glass.

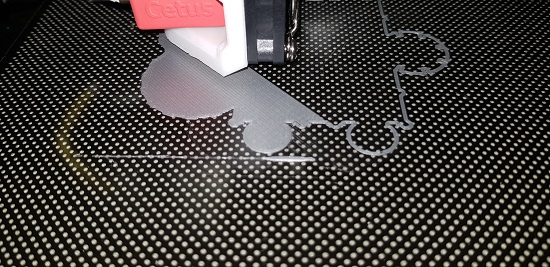

In the Print Settings set the nozzle offset to the chosen layer height, as you had in mind. Here’s a photo of my Mk3 printing on the heated bed with stock perforated board + 0.2mm PEI sheet.

Well yes thats what im thinking, If I set the nozzle height very close the the bed (0.05) and I print with a zero offset wont the slicer know where zero Z is and then move up 0.4 for the first layer to print, if printing @ 0.4 layer height for example?

If ? use a 0.4 offset, wouldn’t the nozzle then be starting the first later at 0.8, .4 offset + first layer height…?

All clear as mud!

Nozzle height + nozzle offset is the starting point. Pretty clear to me.