I have modded my Cetus, mostly mechanical mods to strengthen the backbone of the printer in my quest for ultimate quality and speedier printing above 100mm/sec.

Every now-and-then I see small artifacts on the surface quality and infrequently I see the odd missed-step from a stepper motor. So now that my z-axis is rock-solid and connected to the build-plate axis via a robust backbone, I’m chasing after the last few niggly things that contribute to a random surface artifact appearing on the print surface. I’m not seeing many, but nonetheless …why?

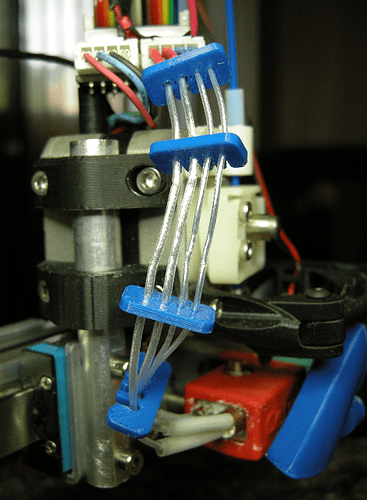

On a hunch, I decided to reroute all wiring that is what I would consider too close to a stepper motor. The connector board that sits on-top of the extruder motor has always bothered me so I removed the printed nylon-mount underneath and installed a 10mm round spacer creating some space between the extruder motor. I also removed the yellow jacket that bundles the wires to the heater-block and printed some wire spacers that separate each wire by 1.5mm.

To my surprise, when printing, the heater-block temperature has never been so stable. I really didn’t expect such a huge improvement in the temperature monitoring within UPStudio. In the past, the temp has always fluctuated at least 1degree up to 5degrees and at times struggled to stay in the optimum range for a given material. But now, wow…a more even/consistent surface quality when printing exotic filament like Ninjatek Armadillow and Cheetah filaments.

Such an easy few-things that anyone can accomplish to get a better surface finish on their prints!

cheers and happy printing folks!