We have a Cetus Tier Time MK3 Extended 3d Printer. The machine is now having a hard time printing circles. The edges of the circles are flattened off and look more like ovals. Also edges of prints are not bonded. Do you know what could be the problem? Images attached for reference.

Thanks

@Jlindner , need some details to pinpoint the the issue… material type, what temp are you using and can you measure the temp at the nozzle, nozzle size, layer height, z-offset, calibrated print-bed lately, was a raft used, print-speed, have you performed general maintenance like checking if the bolts that mount the heat-block are tight etc etc. Also, your pics are out-of-focus… the background has more focus than the prints. Photographing white is difficult but doable.

Looks like you have a number of issues, adhesion for sure, could be caused by a number of things but without all the details it’s difficult to troubleshoot and too time-consuming for those willing to help.

-Brent

Hello @techsalad.

Material is PLA. Nozzle temp is 220 C. Layer Height was .2. Nozzle diameter is 0.4. I calibrated the bed the other day. Replaced stock perforated fiberglass platform with solid machine ground MIC6 aluminum at .125" thickness. The Ceetus customer service people said it could be tension plastic holders. I have since reprinted the tension plastic holders and was going to replace.

Thanks

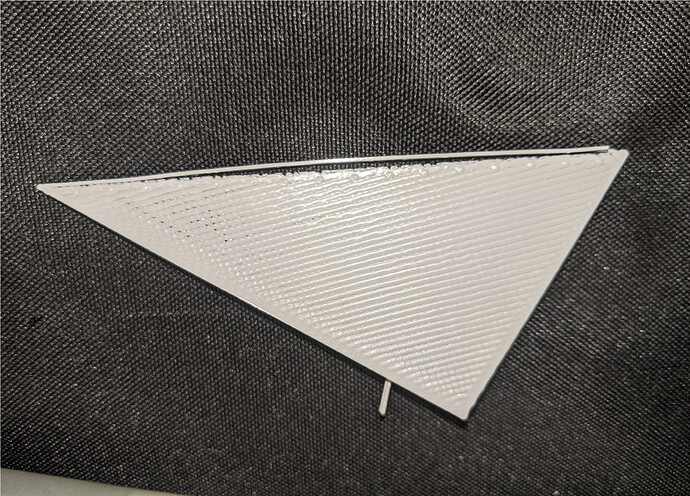

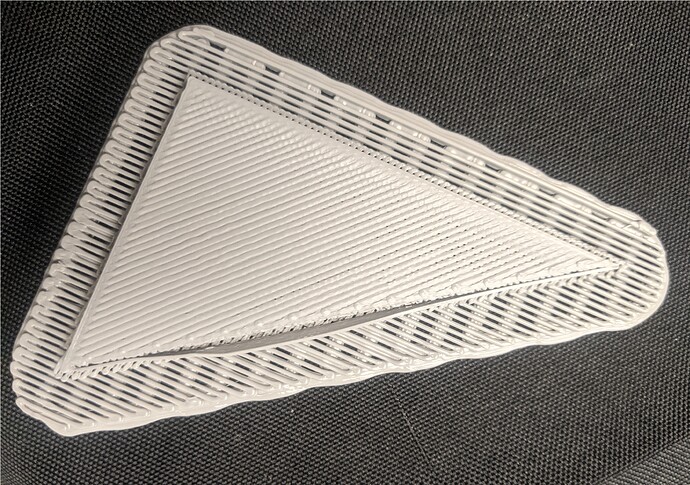

Hello @techsalad as I mentioned briefly before, one of the Cetus Tech support people recommended I reprint the Plastic tension holders and install. I have reprinted them in the same settings as mentioned above. However the holes are still coming out quite distorted and not circular more oval like shape. Image is attached for reference.

Thanks,

Josh

@Jlindner , Hey there Josh …the tension plastic holder pic is too out-of-focus to look at. The triangle pic is much clearer now but still doesn’t allow me a clear view when I zoom in.

In the triangle pic that wall that fell over indicates there’s not enough cooling.

Those layer lines are quite wobbly, check that all bolts are snug, especially the two that attach the heat-block to the frame of the extruder assy, to do that you have to be careful not to push the extruder assy too far to the end of the y-axis, only go as far as required to check and tighten those two bolts.

The balance of filament-flow, layer-height, line-thickness and print-speed are not correct for a .4 nozzle. It looks to me your layer lines are too fat and rounded and they look much wider than the layer lines of the raft. The layer lines of the model being printed should be flat on top and the only way to get to flat on top is when the balance of those settings are correct for the nozzle size. You didn’t provide what line-thickness you used for these models…need all the settings Josh. It might be best if you provide screen-prints of all the settings used to print these models, please include the material profile along with the other settings screeners.

-Brent

@Jlindner , forgot to ask about :

Did you calibrate the bed and then replace bed with the .125" MIC6 bed? If so you need to calibrate again for the new bed.

yes it was calibrated for the new bed