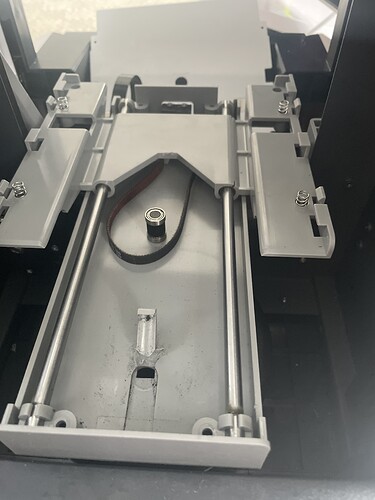

I have bought two up mini 2 a few years ago that have not been used much. Now I have started using one of them and the bottom belt breaks off. When I open the plastic box for the axis I can see that the plastic bar that is supposed to hold the ball bearings at the opposite end of the belt (from the stepper motor) has been broken off. This is really unacceptable and clearly a manufacturing flaw.

I have looked online but have only found one post with similar problems, so I am wondering what the practice is to do in this situation - I feel that this is tiertimes responsibility. See pictures below - any comments suggestions etc please do reply.