I was wondering if it was necessary to set the nozzle height/offset for all 9 points in the calibration menu.

I was wondering if there was a way to make the printer auto stop printing when an error occured

Any and all help is appreciated.

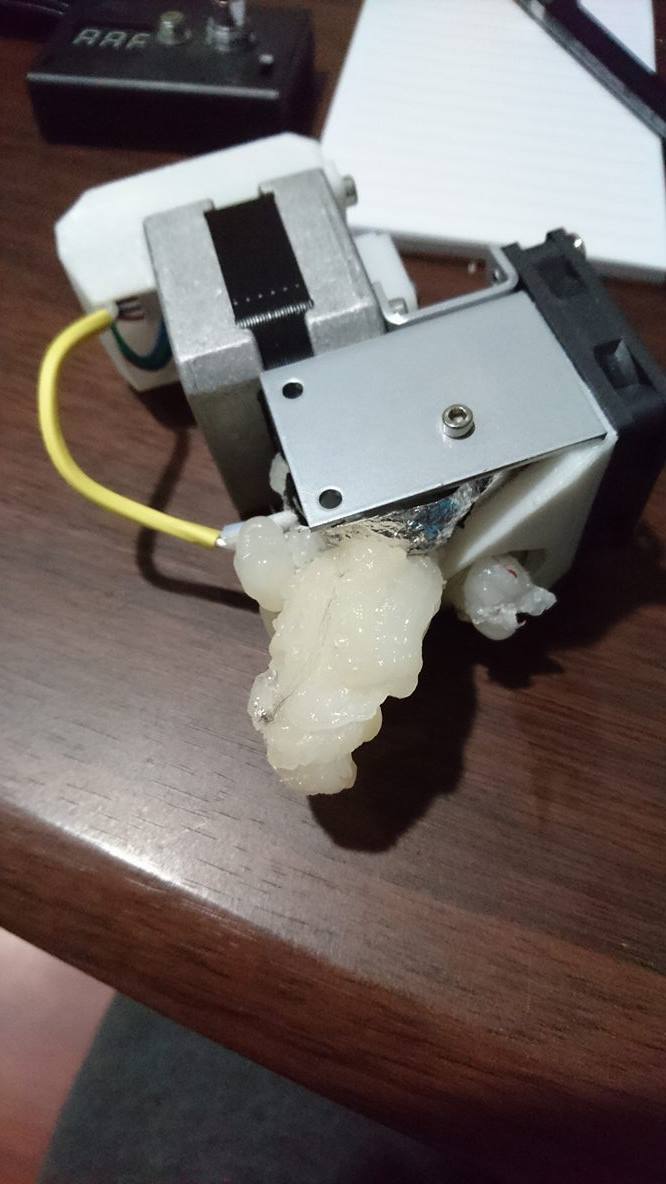

I'm trying to determine the cause for why my extruder is currently ruined.

My nozzle height was calibrated according to the manual and I had a lot of success printing smaller items in the center of the print bed.

Last night, I tried a print that covered more surface area, going from one corner of the print bed to the other.

It seems that while I left it to print for 3-4 hours, the raft somehow came off of the print bed and got itself stuck to the nozzle.

This caused a clog in the nozzle, but it kept going due to the lack of a safety/autostop function.

This is whas my extruder is like now.

I suspect that the nozzle kept hitting the raft causing it to separate from the printbed.

If anyone has any other ideas for the possible cause of the problem, then that would be appreciated.