The point is you have to allow UP Studio to download the latest material profiel ID from the cloud and then change the material setting in UP Studio to reset the profile ID.

Ok, how do I know if the latest profile is downloaded?

I dont know, may be keep it connected to internet for 30minutes?

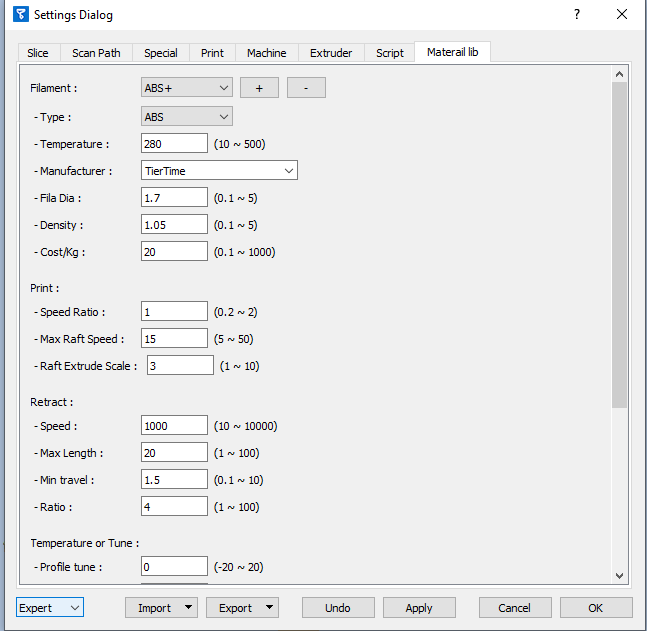

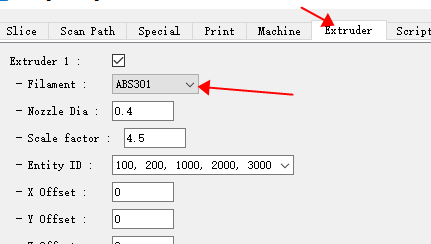

Also please make sure these setting are matching:

I have them both set to ABS+ in Catfish.

I’ll leave Up studio running for some time and see what happens.

Some off things I’ve noticed so far:

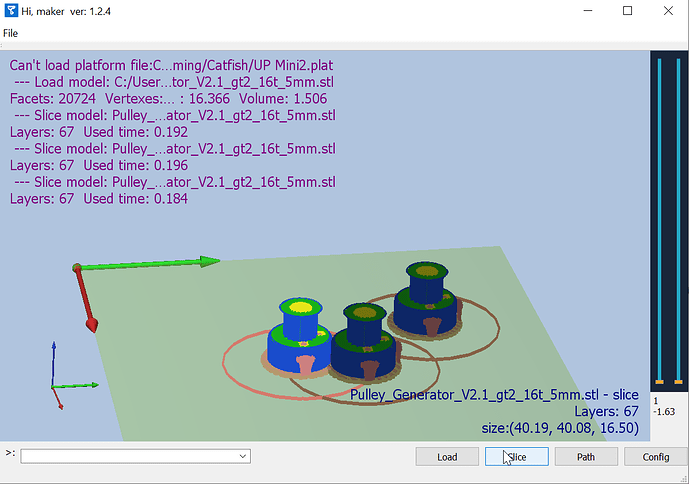

Each consecutive layer when slicing has a different profile width. E.g. if I set “profile” to 2 every 2nd layer has an edge width of 2 but every other layer is 3. I guess this would print okay but I don’t know if it’s intentional.

Also if you slice, change something and slice again the old slicing is still there. So you need to select and remove the old slicing otherwise you get overlapping slicing and you can’t see what actually going on. This happens if you change slice setting or move or rotate a model.

I still have had no luck getting it to start on ABS+. I can however print using the ABS material.

@Jason-TT can you please confirm that using ABS+ does work on UP300 with Catfish 1.2.4_0944883400.

I left the printer and PC idle for an hour but there did not seem to be any material updates.

Settings in Catfish are below:

So some preliminary results between Catfish and UpStudio Slicers.

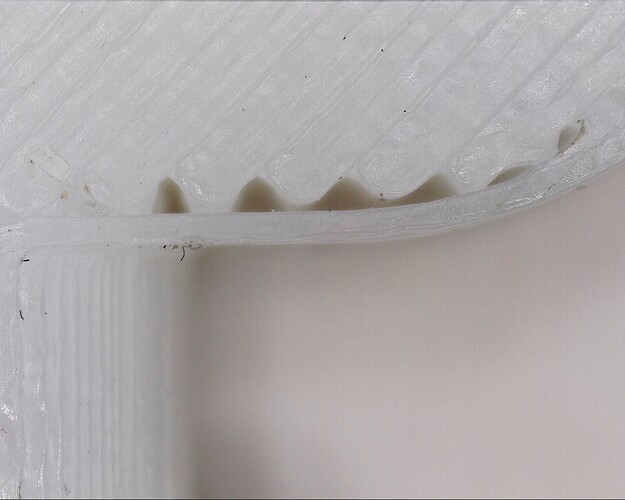

Below is a simple part; the white one is printed in ABS+ sliced using UpStudio, the other one (yellow) sliced in Catfish using ABS. I don’t expect the material change makes much difference but I’m unable to print in ABS+ using Catfish at the moment because of issues listed in previous posts.

You can see from these parts that the white one (UpStudio) has holes and gaps near the base of the key handle that extend all the way through the part. Closer images below:

The UpStudio print is using 99% fill, 0.1mm height, normal speed. The Catfish print is 100%fill, 2 layer contour, 0.1mm height, normal speed.

There is a big difference here in the fill. It may not seem like much but this is the first time ever I’ve been able to print with more than one contour and at 100% on my UP300. This is also the first time I’ve been able to print without gaps in the flat surfaces.

I should point out the Catfish version pulled away from the raft a little but this I my fault I think as I selected hatched raft instead on using the default raft in catfish. I think in this mode it bypassed the bed leveling in the UP300. I will try again later and check the result.

So in short I think Catfish is looking promising. There are short-comings for now like the usability and not being able to change individual supports like in UpStudio but this is not supposed to be a finished product yet.

I will be using Catfish for any engineering parts that need strength or tapped holes. If I can get ABS+ working that would be ideal.

For anyone having the edge peeling/infill issue I would recommend to use Catfish.

@BigE79

That’s excellent info and shows very promising results, thanks so much for taking the time to do the trial and for posting the results. ![]()

I have a question for Tiertime:-

“Why are you not posting information and photos like this yourselves every day, or at least every week?”

I ask as a long time TT user and supporter who’s been giving serious thought to walking away from TT products. Product delays, bugs that don’t seem to be understood let alone fixed, and a certain promise that wasn’t delivered upon were just about the final straw. To see that there is good stuff coming, and that it isn’t “just words” would go a long way to turning unhappy customers into happy ones.

You’ve done the hard part (the engineering) you just need to do the easy bit (telling people about it).

This is a quote from another supplier I use:-

After receiving feedback from many users, especially on the forum (thank you!), we have made some additional improvements…

This was referring to a new feature introduced on their three week update cycle. We as users asked for some changes and they were implemented in the very next release. Not only that but after posting on the forum a member of the dev team reached out personally to ask for feedback on how to improve the feature. That is how customer service is from a good company these days…

Regards,

Owen Sparks.

I can confirm now that printing using Profile raft instead of Hatch works better and I didn’t any part lifting off the raft.

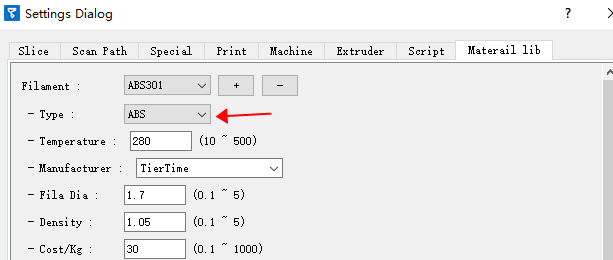

@Jason-TT. Regarding the ABS+ issue. In Catfish the material profile for ABS+ (in material lib tab) uses ABS as the base material just at a higher temperature. Do you think this is why ABS+ is not working on the printer; because it thinks it’s ABS?

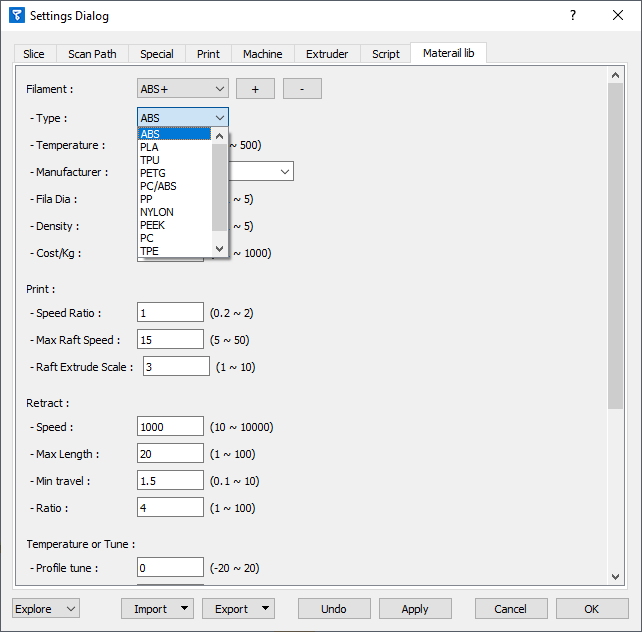

I can’t find ABS+ in the “Type” pull down field:

ABS+ should belong to ABS type, but not sure what happened, we will look into this.

A quick fix would be use ABS profile and increase the print temperature for 5-10 degrees as other setting for these two profiles are almost identical.

I’ve tried submitting the registration form twice now, most recently yesterday but no email. Are there any additional requirements for this?

Why add the complexety of .tsk files instead of g-code output? that would render the need to sync material profiles as all the information the printer needs would be in the g-code no?

@bjorn Catfish can output Gcode. If running on an UP300 however it does not support Gcode import.

Still waiting for the registration to come through so I can try it on the Up Mini 2, that may or may not support g-code. Hopefully that takes care of the material voodoo. Thanks for reporting back @BigE79!

Will it be compatible to Cetus MK2?

I think it is. Looking through the software, one can select Cetus or Cetus_H as the desired machine to slice in.

The slicer is designed to work with 3rd party and all Tiertime machines I’m pretty sure. Some of the older Tiertime UP printers might need a CPU upgrade to be able to read the gcode or updated proprietary output language better.

@Jason-TT does Catfish try to move away from the use of stepper motor language as present with UP Studio’s slicing method, and more with gocde or a proprietary variation of gcode for Tiertime printers?

My guess is Catfish outputs a proprietary version of gcode for Tiertime printers, hence how it is able to slice considerably faster like we’re used to in other programs like Simplify3D

Code received, looking forward to testing next week!

Seems to be a bug where moving the model after having sliced it will either duplicate the model or not clear the previous toolpath preview.

The Catfish will replace UP Studio, for those who feel UP Studio is too limiting.

UP Studio will still be there as a basic, easy to use program for general printing and beginners.

For advanced or Pro users, Catfish is made for them, there is no limit on the settings, so its easy to make mistakes if the user is not familiar with the settings but there is no limitation.

We will provide more toturials later, to explain how to use the settings.

The previous tools paths will not be cleaned unless, deleted by the user.

So that you may able to compare different tool paths if you want.

Hi Jason, this sounds good.

I’m having problems getting Catfish to work with my UP Box upgraded to a Box+ through the wireless CPU upgrade kit.

I’ve tried slicing using standard Tiertime ABS and ABS+, as well as UP Box and UP Box+ selected as the machine in the program. I made sure I put in the nozzle height value from UP Studio in and also changed the material profile to the materials so there wasn’t a mismatch there.

I’m using the latest Catfish Beta revision for Mac and the latest Mac UP Studio version. I think there’s an issue at the moment using it all with Mac. I’ve sent out a registration code to try on Windows, haven’t received yet though.